Explore our extensive range of video materials below.

Standard 1-year warranty on your purchase

Specialist in steel cables since 1960

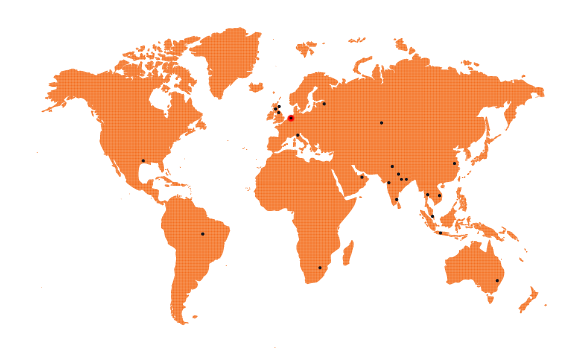

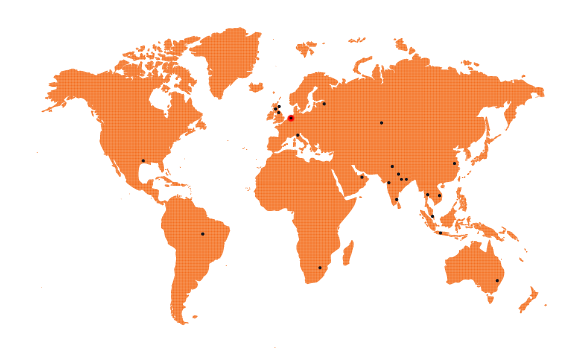

Active in more than 40 countries

100% certified and quality guarantee

Discover the world of steel cables: Learning Centre and informative videos.

Welcome to our Learning Centre, where we provide a variety of information about steel cables. Our videos are designed to provide insights into various aspects, including types of steel cables, components, and constructions. Explore the diversity of steel cable applications and enhance your understanding of the features that make each cable unique.

Quote requestLearning Centre

Usha Martin Europe – Expert In Steel Wire Ropes Since 1960

Compacted Strands – Wire Rope Components

Rope Lubrication – Wire Rope Features

The amount of lubrication shall be customized depending on the application. Dry ropes are used for peculiar environmental conditions. Core lubrication and minimal lubrication during closing is typical for industrial cranes. Lubrication during core closing and final closing is usually required for Oil en Gas cranes. An additional post lubrication can be required for subsea cranes.

Plastic Impregnated Core – Wire Rope Constructions

The application of plastic between the core and the outer layer creates a mechanical connection between the strands and increases the resistance to side deflection. It is typically used in 8 and 10 strand boom hoist ropes, working with fleet angles between 2 and 4 degrees.

Breaking Force – Wire Rope Features

Wire rope breaking force can be minimum, actual or aggregate. The breaking force depends on the rope grade, the metallic area and the spinning factor.

Rotation Resistant Ropes – Wire Rope Constructions

A rotation resistant (or non-rotating) rope is a rope having the direction of lay of the outer strands opposite to that of the core. The type of construction gives better rotational stability, and it is therefore typical in case of single fall lifting or multiple fall lifting at relevant heights.

Selection Of Lay Direction – Lay Type And Lay Length

A rope can be righty or left hand depending on the winding direction of the strands. In the designation, the lower case letter (z, s) indicates the direction of the wires in the strand, the upper case letter (Z, S) indicates the direction of the strand in the rope.

Selection Of Lay Type And Direction

The selection of langs or regular lay depends on the desired features. Langs lay offers better crushing resistance. Regular lay increases the torsional and rotational stability. For heavily compacted strands, the benefits in terms of crushing resistance are equivalent, as the smooth strand surface allows avoiding the “gear” effect.

Strands – Definitions And Constructions

There are different kind of strands like Seale, Warrington, Filler and Warrington-Seale. Each with their own specifications.

Retention System – SeaLube

Corrosion protection is an essential feature to preserve rope’s life. Brunton Shaw ropes can be equipped with a special membrane which keeps the core lubricant in place, preventing wash out, excessive leakage and water contamination. This grease retention system comes under the brand “sealube”.

Metallography – Steel Wire Ropes

Metallography studies the microstructure of materials. This helps to understand whether steel wire have been manufactured properly, whether they are reliable and the possible causes of failure.

Rope Damages – Steel Wire Ropes

A rope can be affected by several potential issues that can result in its safety reduction, such as: corrosion/oxidation, birdcage and Wire breaks (external and internal).

Fatigue – Steel Wire Ropes

Fatigue is an inherent phenomenon consisting of a progressive damage due to repetitive stress. At Usha Martin Italia, rope fatigue is assessed on a rotary bench, on which the rope turns around its own axis with no interaction with sheaves.

Preformation – Steel Wire Ropes

Preformation consists in a strands permanent deformation in order to impress the tight helix. It is an essential feature which determines the behavior of the rope in service and depends on the rope type, use, and application.

Bending Test – Bicycle Test

“Bicycle” test allows to check the rope reaction under sharp bends and the uniformity and reaction of the outer strands when the rope comes back to the original position.

Screw Driver Test – Steel Wire Ropes

This test allows to check the outer strands’ toughness, that depends on the preformation level also. Depending on the necessary pressure to insert the screwdriver blade between two adjacent strands, the force to open them and their reaction at the screwdriver extraction, it is possible to evaluate some rope functional parameters.

Steel Wire Rope Measurement – Lay Length

The lay lengths is that distance parallel to the longitudinal rope axis in which the outer strands of a stranded rope or the outer wires of a spiral rope, or the unit ropes of a cable-laid rope make on complete turn (or helix) about the axis of the rope. Lay length is an important wire rope geometrical parameter and indicator, and it can be measured in different ways.

Steel Wire Rope Measurements – Diameter

According to EN12385-1, ISO and API standard, diameter measurement has to be taken on a straight portion of the rope, either under no tension or a tension not exceeding 5% of the minimum breaking force at two positions spaced at least one meter apart.

Locations